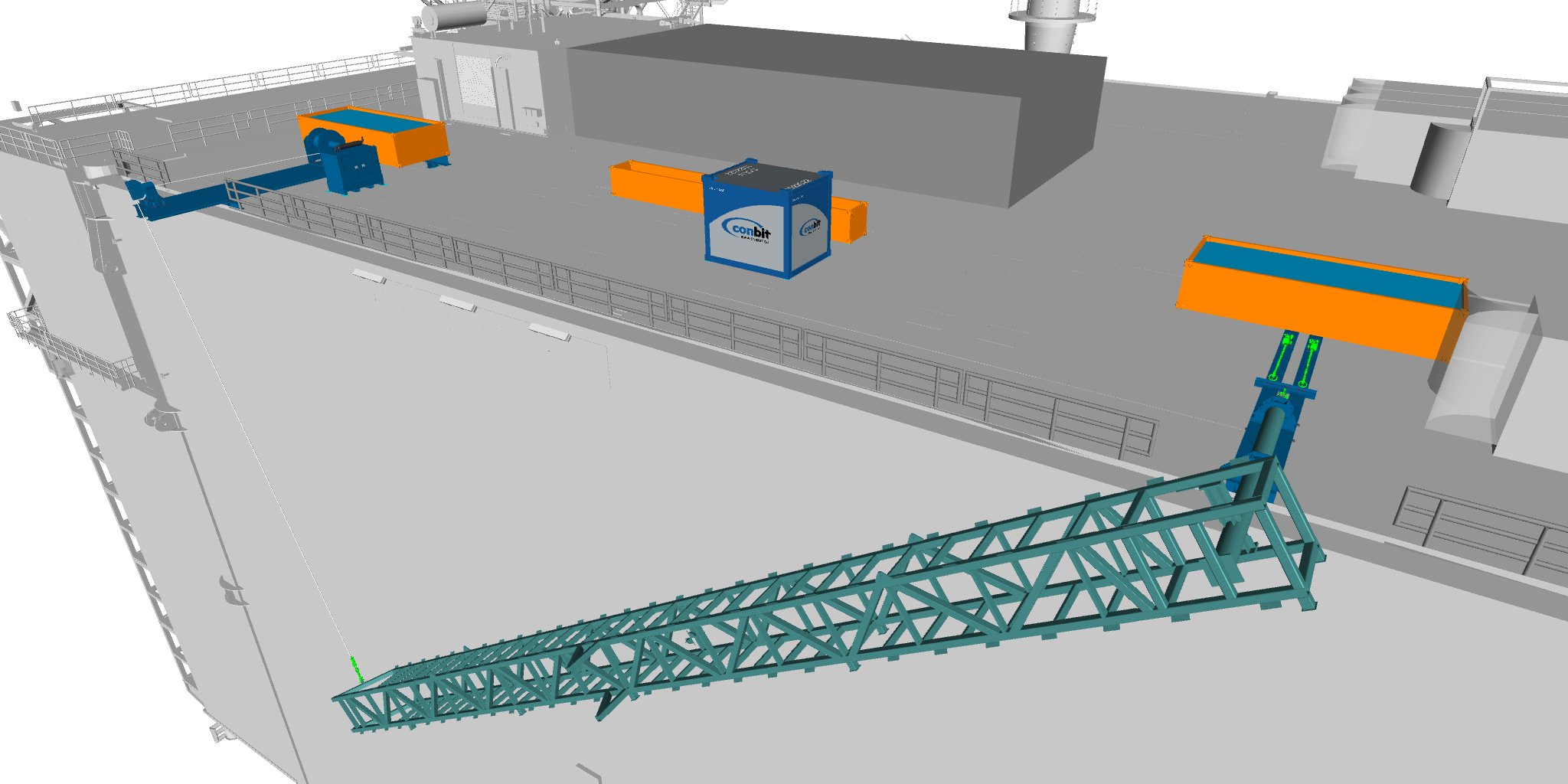

UPENDING

The main challenge was upending the riser. As the platform’s crane was inadequate to perform this task, we made use of the substation’s height to upend the riser. By first sliding it out of the platform and supporting it at one end with a hinge point and then lowering it at the other end with a winch, it was slowly brought into the vertical position.

LIMITED WELDING

Our client wanted to keep welding of temporary structures to a minimum. The Conbit engineers came up with a novel solution. This enabled us to limit the welding to only a few shear plates.

OVERBOARD WORKING

Overboard working normally requires additional measures to maintain safety, including a standby rescue vessel. Therefore, the client decided to prevent overboard working. As we were lifting overboard, we needed to remotely release our lifting slings. We used a remote release shackle to overcome this challenge.

AIRTIGHT WALL

Because the substation’s outer wall is airtight, caution was necessary to ensure that the riser did not impact and damage it. Therefore, during the installation we decided to execute the upending procedure with extra clearance between the riser and the outer wall.