LIFT BELOW HELIDECK

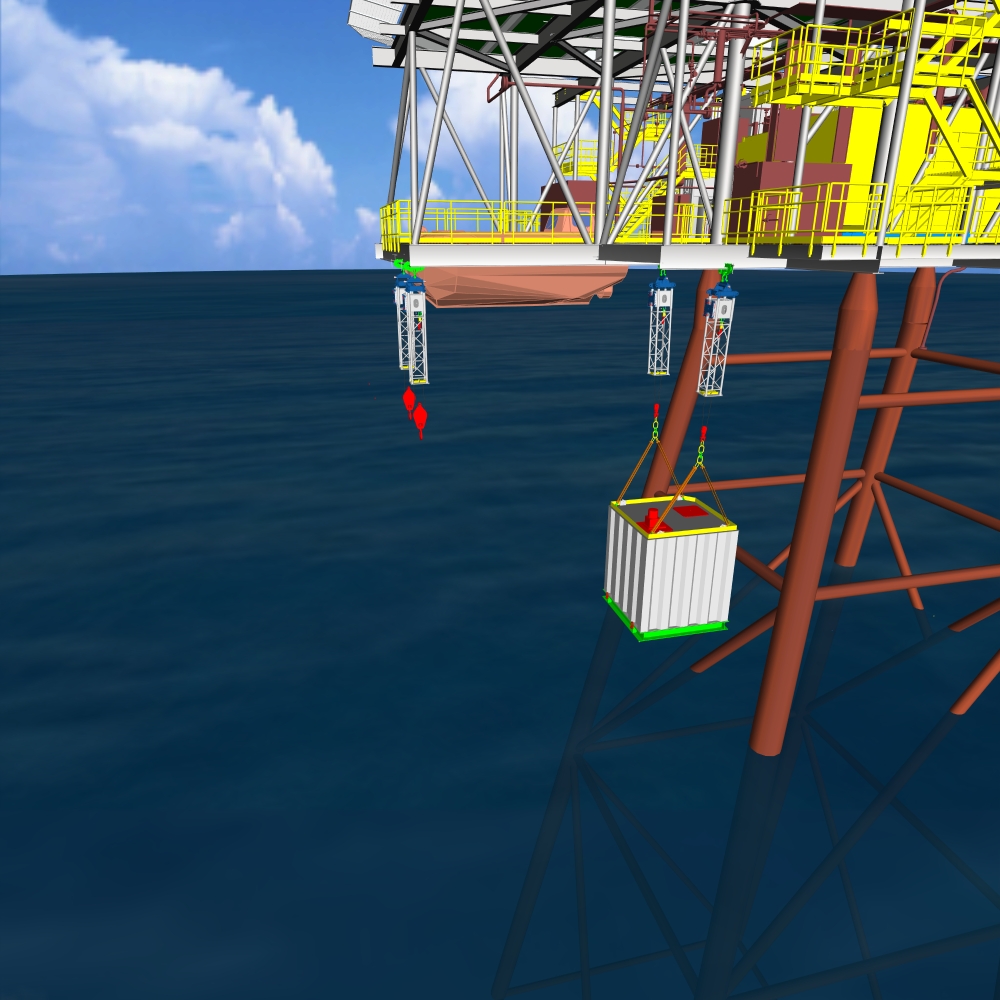

During the engineering phase, a new type of lifting method was proposed for this below deck lift. Proven technology was used in the chosen configuration but the application of this technology was the first of its kind.

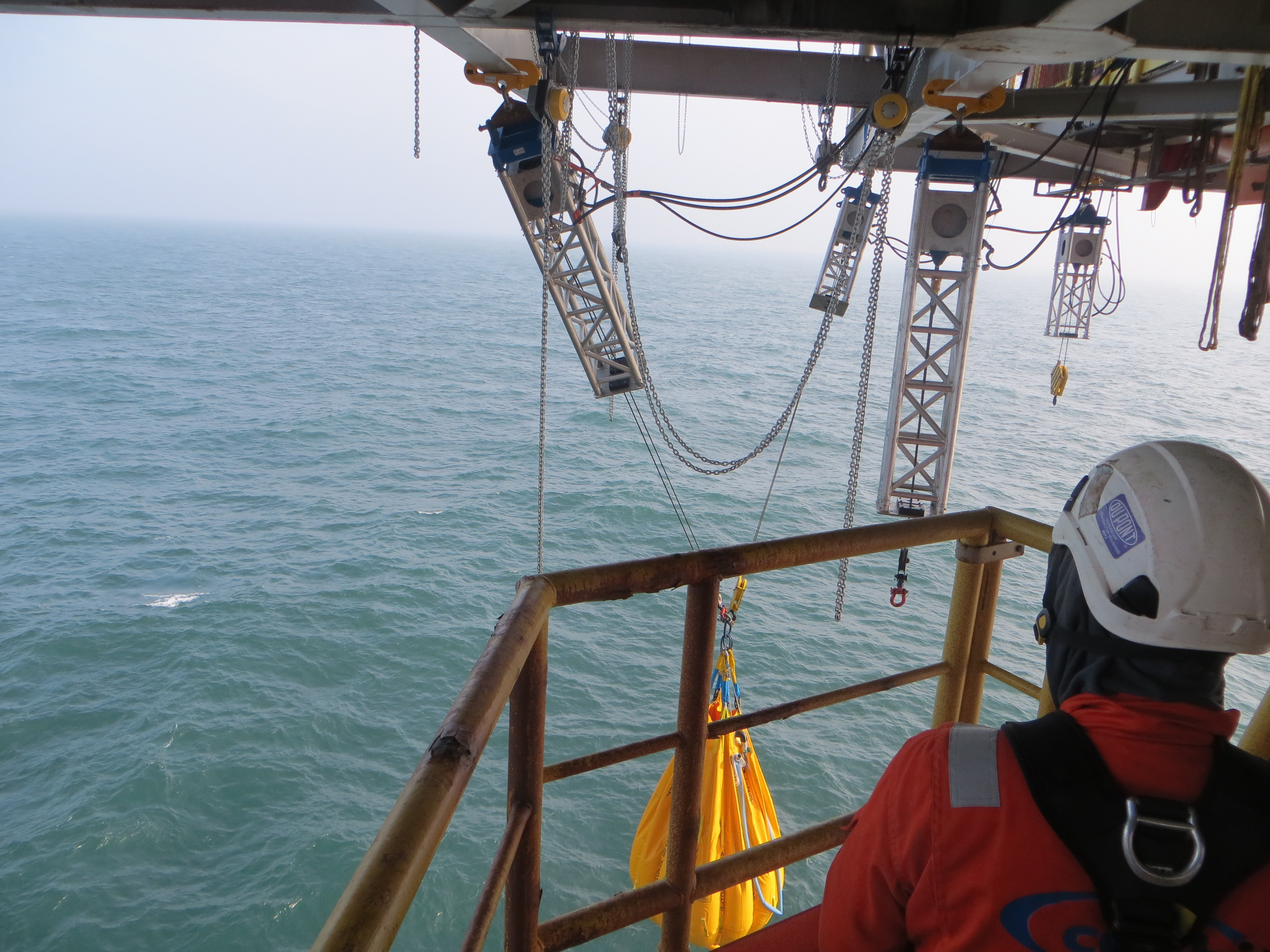

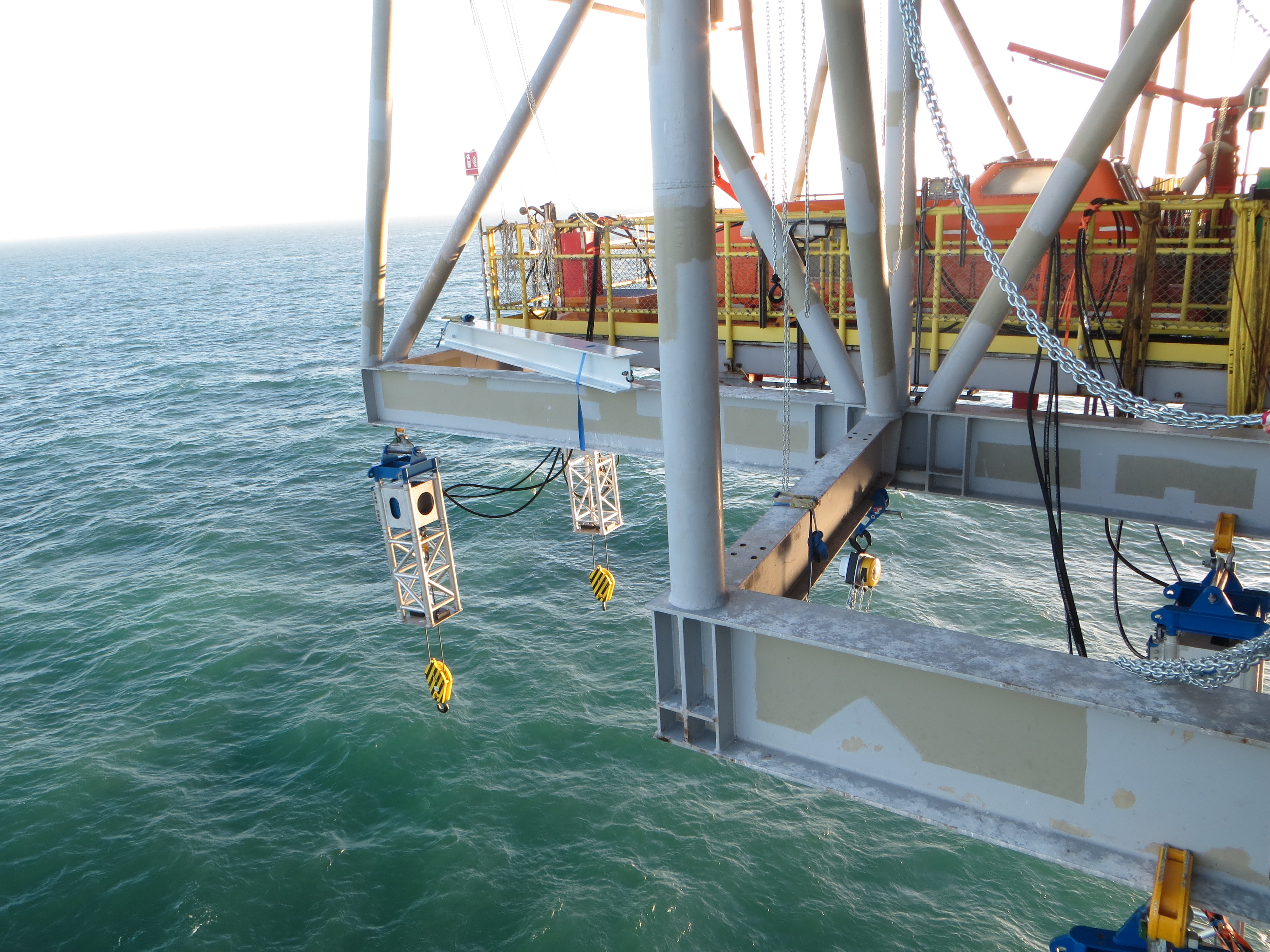

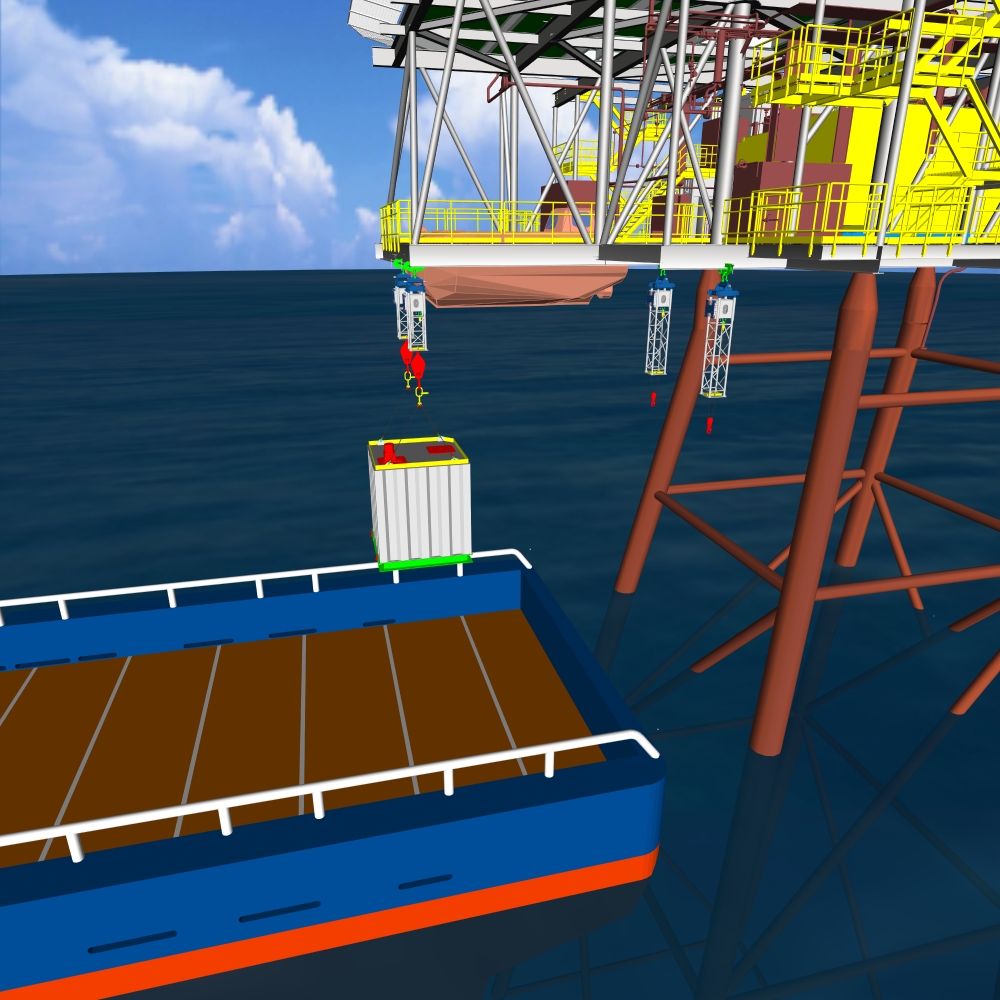

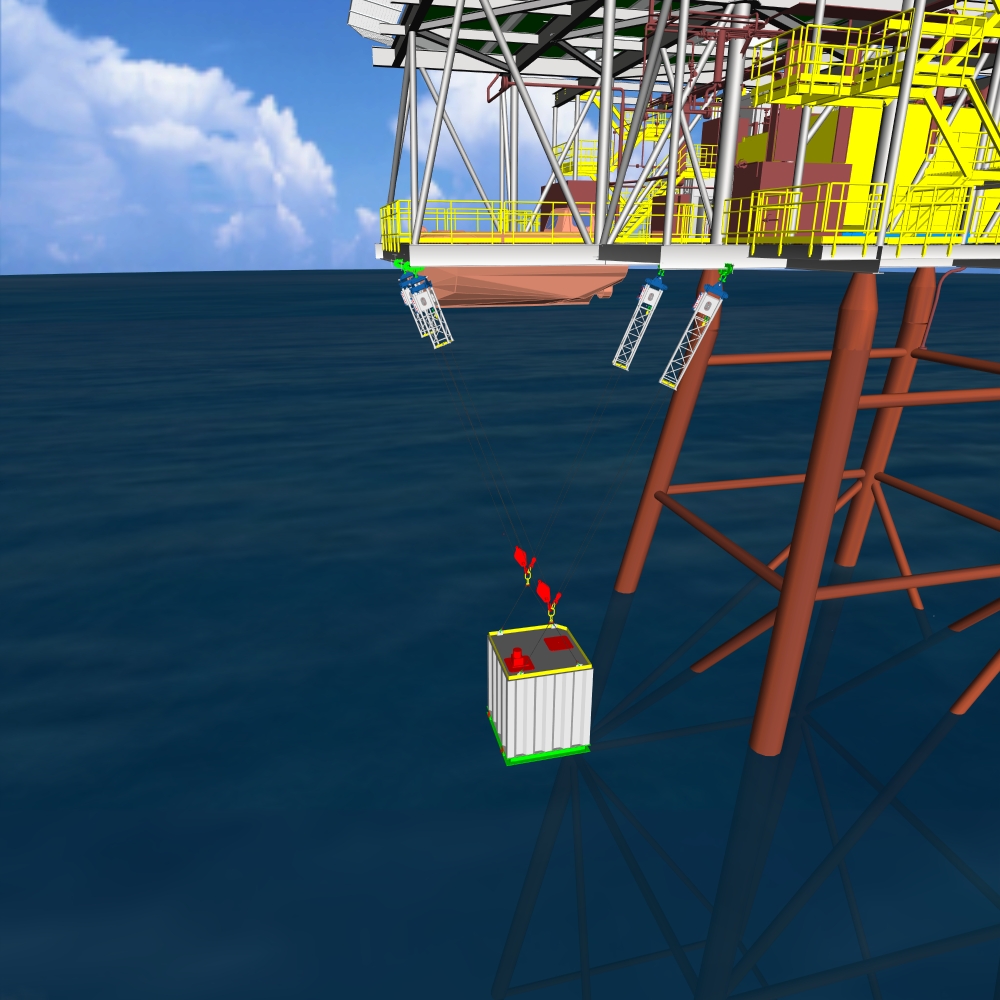

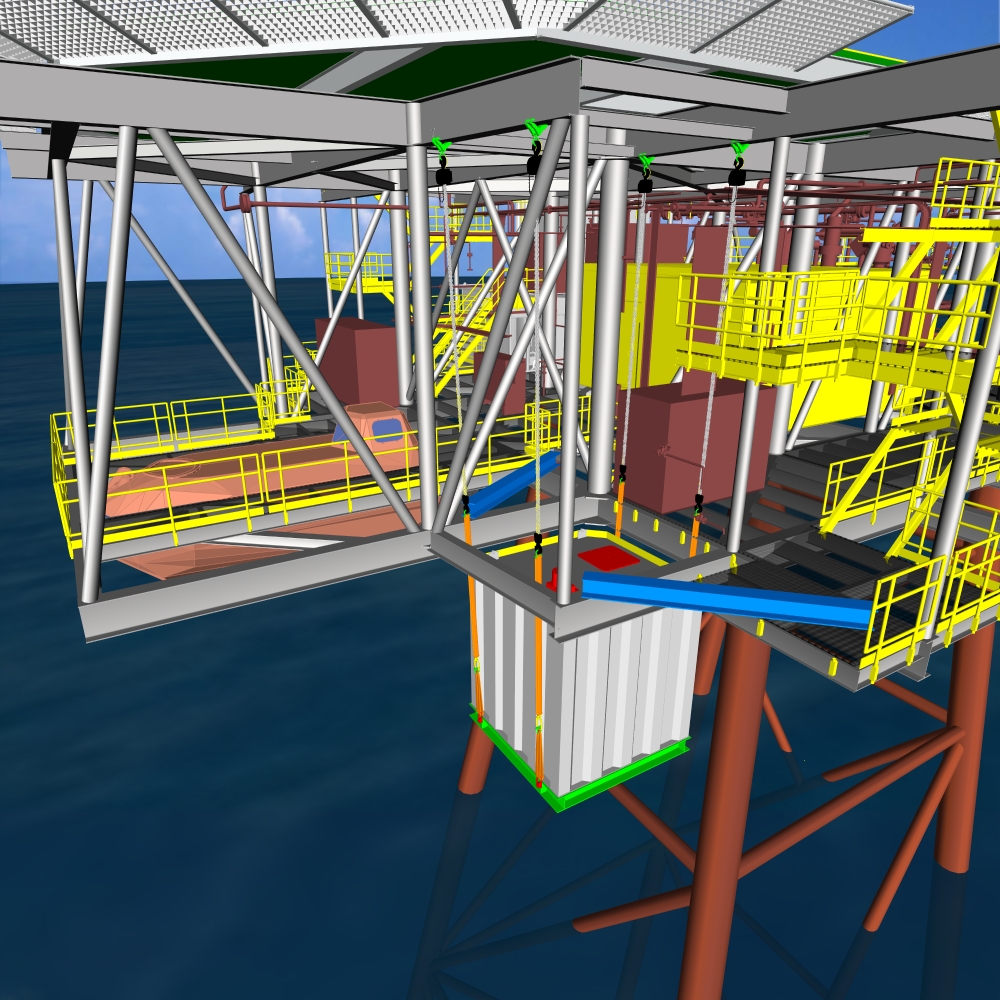

The main components of the lifting configurations consisted of four winches which were able to operate at the same time and speed. As the winches would be located underneath the helideck and would hang freely, the winch wire needed guidance. The Conbit engineers used trusses that are used within Conbit on a daily basis to guide the cable to the hanging winches. This lifting configuration proved to be very flexible.

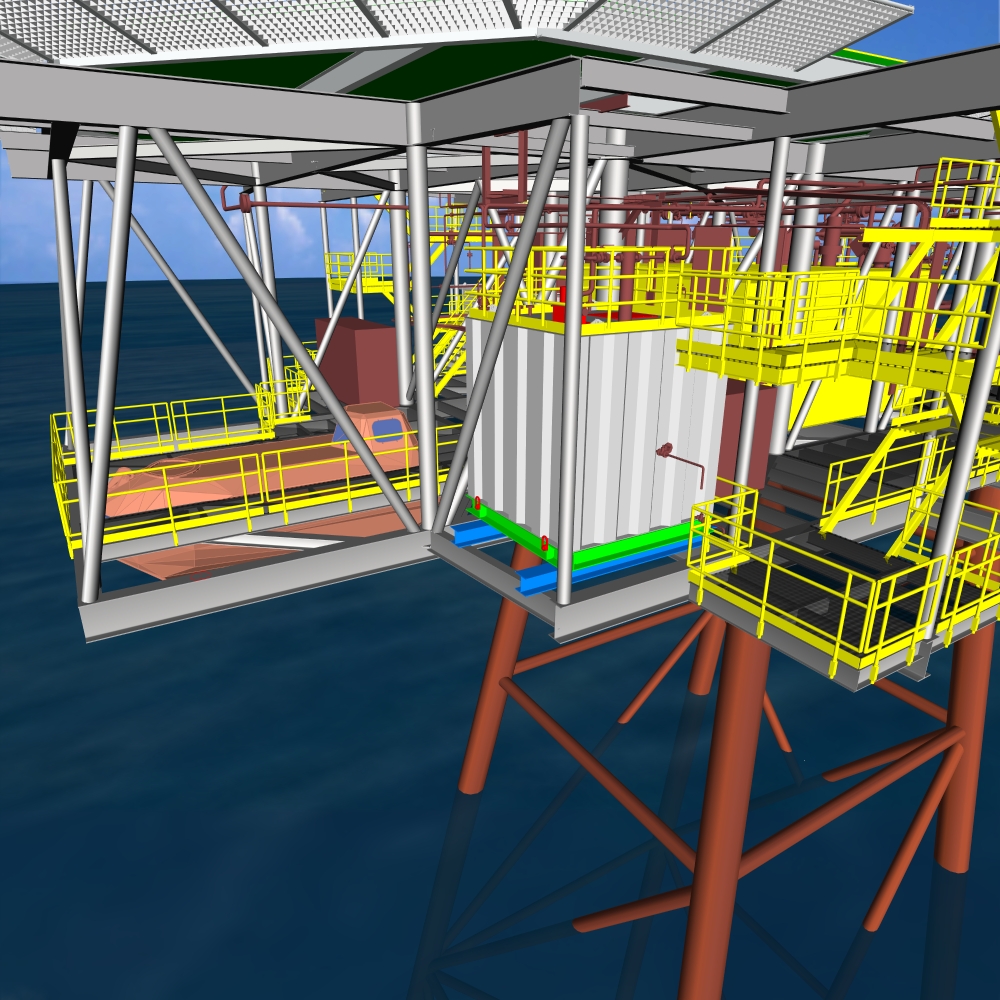

The lifting system was installed and tested prior to the arrival of the supply vessel. Once the vessel had arrived, it approached with the aft towards the platform. The lift lines were attached to the tank which was rapidly lifted from the supply vessel. When the tank had been lifted high enough, the supply vessel moved away from the platform and returned to shore. After offloading the tank was moved by second lines to the next two winches which would lift the tank to its final location.

The project proved to be a great example of the expertise of Conbit and the excellent cooperation with the very competent team of Centrica in Hoofddorp. The project demonstrates Conbit’s ability to perform lifting operations underneath a deck. The service offers platform operators a very safe and efficient alternative to large crane vessels.